![]()

VBL provide OEM manufacturing for metal stamping. We can manufacture the products with various material. Below are the common type material: 1.Cold Roll Steel (CRS): SPCC (DC01), SPCD, SPCE

2.Stainless Steel (SS): 304, 301, 316, 316L, 410

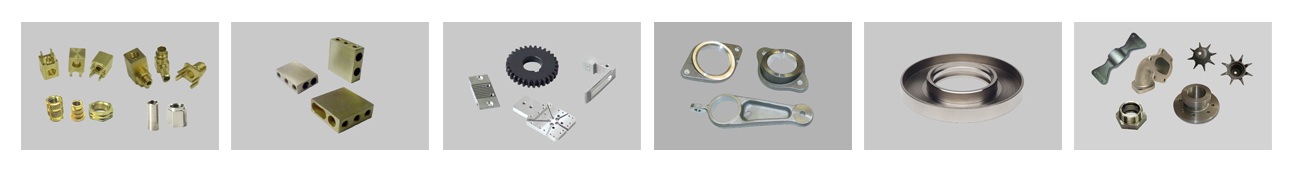

3.Copper: C1100 (Copper), C2200, C2600, C2680 (Brass), C5191, C5210 (Phosphor Bronze), C7521 (Nickel Silver Alloy)

4.Aluminum: 1100-H14, 3003-H14, 5052-H32, 6061-T6 etc.

5.Pre-Coating Steel: SECC, SGCC, SA1C , SPTE etc.

If you have other material not shown above, please contact us for enquiry or request of quotation drawings. Our product can be made with post processing as: 1.Plating: Zinc Plating (Clear, Yellow, Blue, Black), Nickel Plating, Tin Plating (Matte or Bright), Silver Plating, Gold Plating, Electroless Nickel Plating,

2.ED Coating: Black color and other color

3.Annodization and Chromate Conversion Coating : Black color, Clear, Golden and other color

4.Paint and Powder Coating: RAL or Pantone Color

5.Special Paint: Rubber Paint, High Temperature Resistant Paint

6.Others: Sand Blasting, Polishing, Brushing, Electro-chemical polishing

We can make the metal stamping parts with mechanical assembly by 1.MIG Welding - Gas Metal Arc Welding or Metal Inert Gas welding

2.TIG Welding - Gas Tungsten Arc Welding

3.Spot Welding

4.Riveting

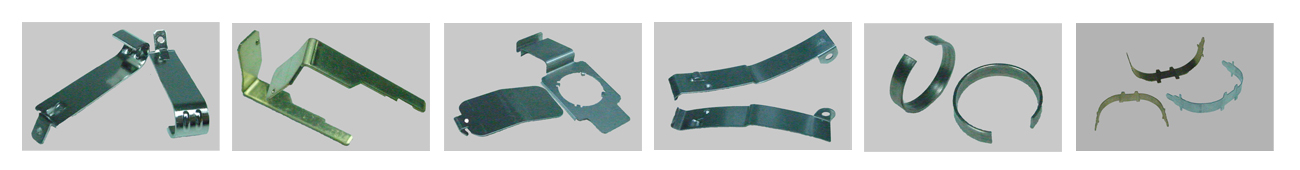

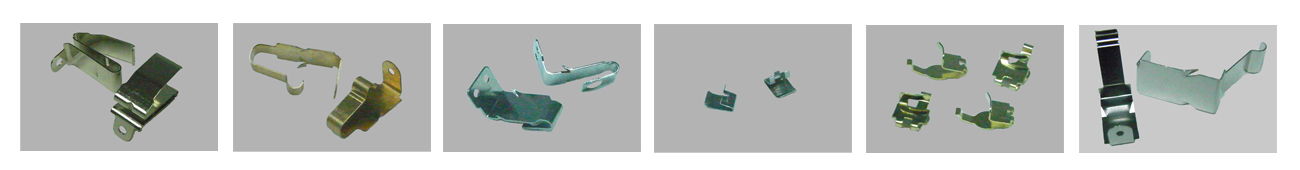

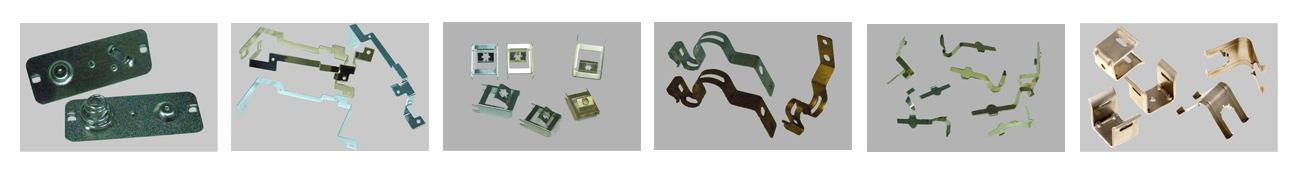

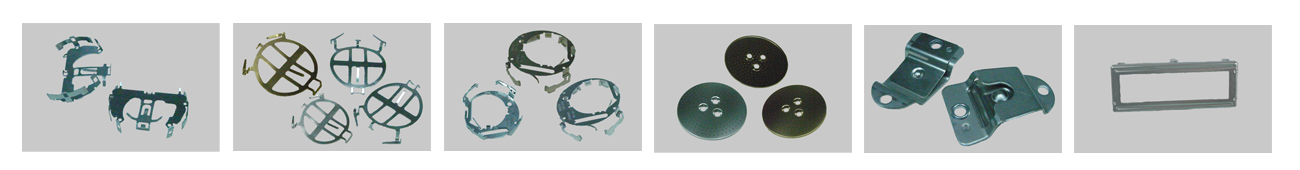

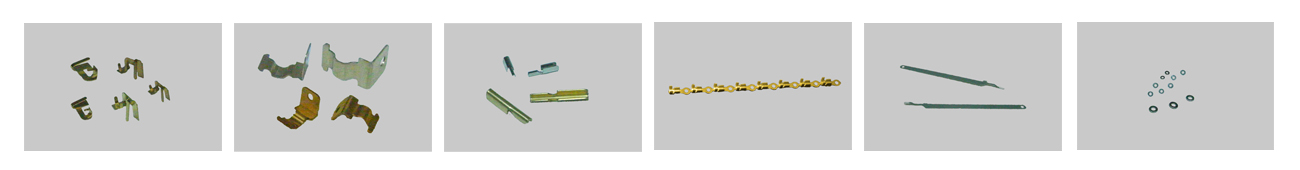

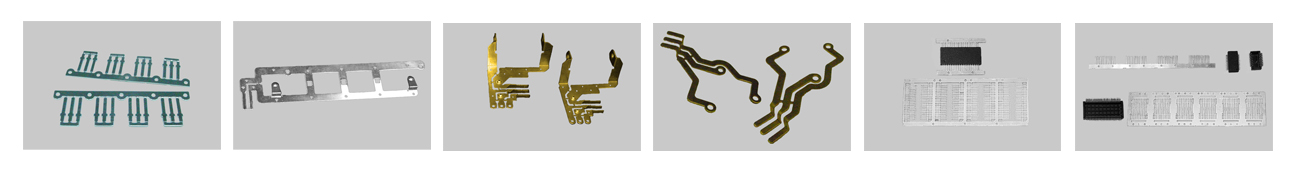

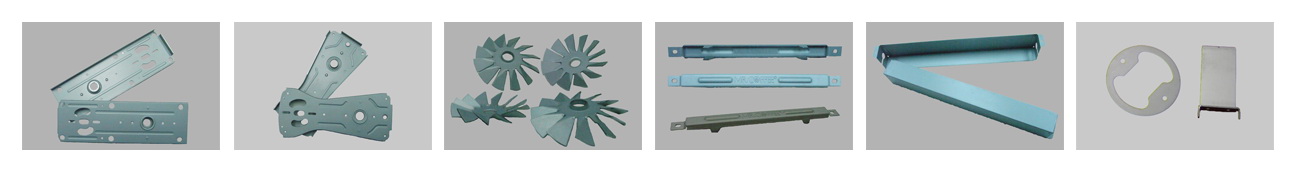

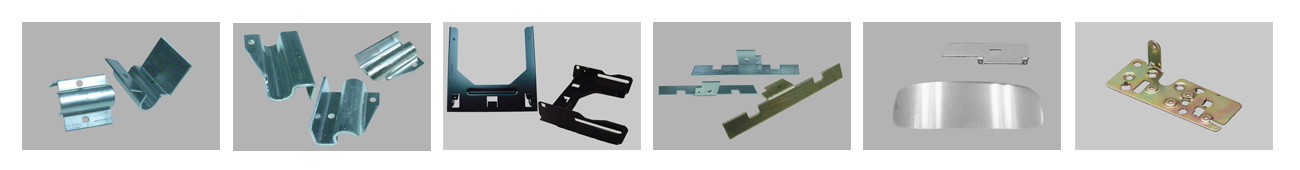

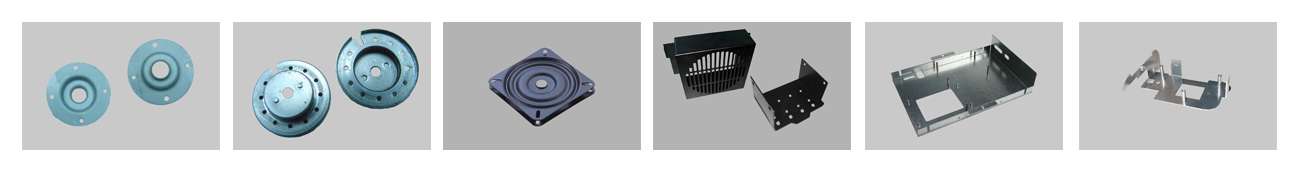

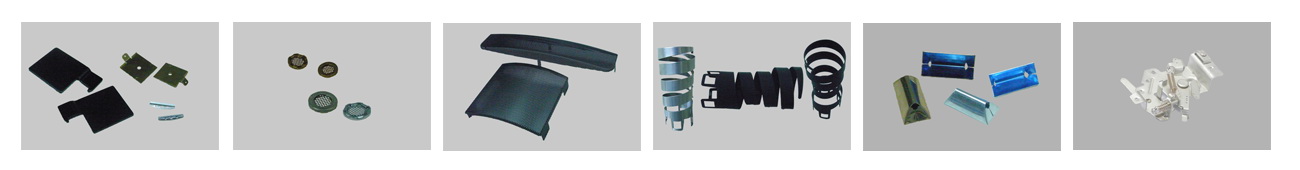

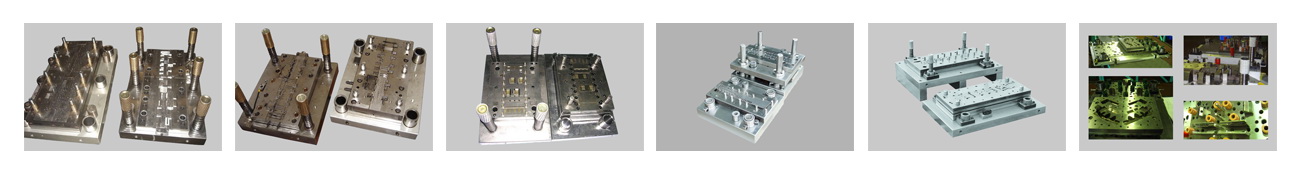

Mechanical assembly is a contract service between your company and VBL to assemble, manipulate, or otherwise alter mechanical parts, components, or mechanical systems. Mechanical assembly can range from simple two-part assemblies to complex multi-part assemblies. VBL's mechanical assembly processes includes but is not limited to materials such as stainless steel, aluminum, brass, steel, bronze, and many other types of materials. Our mechanical assembly process allows us to provide you a genuine mechanical turnkey service. We manufacture of precision stamping parts for electronics, computer, general consuming product, automotive part, and Tel-communication products. If you need a partner who specializes in precision stamping parts , VBL is your excellent choice. VBL offers in house tool and die design, build, and maintenance for progressive, compound, and secondary stamping dies. In house Tool and Die Design has proven to be an extremely economical means of getting your parts to production. Our in-house tool and die design team has extensive experience with progressive dies, pierce and cutoff dies, compound dies, and form dies. This experience translates into immediate time and money savings for you, our customer. VBL’s fully equipped tool room allows our tool and die design team to specialize in hand transfer dies, complex progressive dies, draw dies, and compound dies. Prototyping and plain die tool design enhancement is now available in one seamless process. Whether we build your original tooling or modify and sharpen your existing tooling, our tool and die design department will exceed your expectations. Progressive Metal Stamping The same expert tool and die design team is also one of on staff in our production facility; allowing then to quickly respond to repair and maintenance issues which better enabling us to deliver your products on time – like you expect. Furthermore, our routine maintenance program will ensure you quality production and extend the life of your tooling. Compound Die Compound Dies are applicable in many metal stamping operations. When metal stamping part requires more than one feature to be stamped and these operations can be run independently of one another, a compound die can be used. Compound dies will provide multiple metal stamping features with each stroke of the press. Furthermore, compound dies provide excellent part flatness. Deep Draw Die A Deep Draw Die is suitable for metal stamping parts when the material is required to flow or stretch, as opposed to being bent or formed. It is common for deep draw dies to require multiple steps in order to achieve a significant depth. Form Die Form Dies are probably the most common metal stamping dies used in the industry. Form dies can be very simple to moderately complex. Product and Services: Battery Contact Plate, Contact Plate, Spring Plate

Metal Terminal or Terminal Plate

Metal Washer, E-Ring

Part applied into Consumer Products

Deep drawing Part

Metal Bracket

Metal Case

Others

:

Tooling Manufacturing Equiptments:

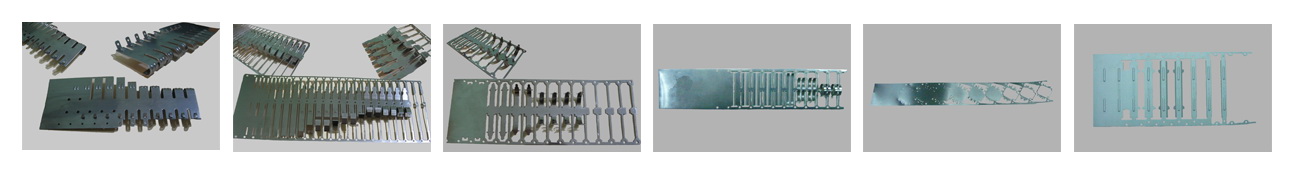

Toolings & Strip:

|

| Victory & Brilliance Limited. All right reserved |